IR-8400D Gas Analyzer

- Overview

- Specifications

- Collateral

- Videos

- Industries

- News

- Parts

Overview

- High reliability and low maintenance

- Explosion-proof enclosure

- NEMA 7 certified

- Automatic calibration and multiple sample stream monitoring (optional)

- Measures up to 5 gases simultaneously

The Infrared Industries IR-8400D is a non-dispersive infrared (NDIR) gas analyzer, capable of simultaneously monitoring target gases in a sample stream for extended periods of time. The IR-8400D Digital Gas Analyzer is designed specifically for the measurement of Hydrocarbons (HC), Carbon Dioxide (CO2), Carbon Monoxide (CO) and Oxygen (O2). The ranges for the IR-8400D are specified by end-user requirements.

Tailored for the petroleum industry, this instrument is designed specifically for enhanced oil recovery applications as well as for refineries and petroleum transfer stations. For example, it can be configured to monitor the level of CO2 present in the separated gas from production wells using CO2 injection for enhanced oil recovery. The IR-8400D is designed to continuously monitor total hydrocarbons expressed as CH4, C3H8, or C4H10 in process gas streams or for ambient air.

The IR-8400D analyzer is temperature and pressure compensated to achieve excellent long-term stability and negates the need for frequent calibrations. Built to withstand hostile temperature and weather environments, these analyzers come standard with an LCD display, an RS232 output, an analog output, and an isolated linear 4-20 mA current output.

Features and Benefits

State of the Art Electronics

The IR-8400D is made with state-of-the-art electronics which is housed in an explosion-proof enclosure. The analyzer is ruggedly built to withstand a long life, insensitive to shock and vibration.

Material

Compatibility is assured by using stainless steel sample cells, sapphire windows and by selecting corrosion-resistant materials for seal and tubing parts.

Temperature

Controlled long-term stability and accuracy are maximized and resistance to harsh environments are minimized with the use of a temperature stabilized optical bench and electronics. An enhanced temperature controller system allows the IR-8400D to accurately measure down to single parts per million (ppm) increments and stabilize temperatures within half a degree.

Automatic Calibration

An operator can select dates and times that the IR-8400D will automatically perform its own routine calibrations and update itself without any operator assistance.

Applications

- Continuous emissions monitoring

- Combustion monitoring for boilers and furnaces

- Monitoring atmospheres in heat treated and annealing furnaces and process stream control

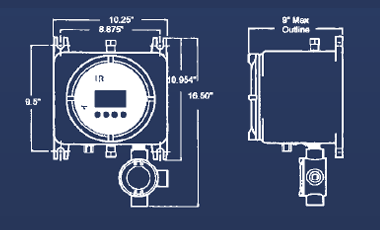

IR-8400D Dimensions & Side View

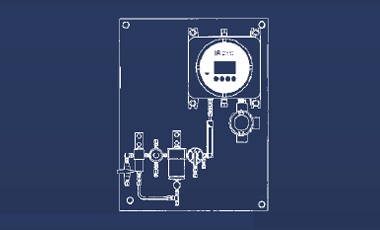

IR-8400D Gas Analyzer with

IR-1150 Sampling Conditioner System

Specifications

| General Specifications | |

|---|---|

| Performance measurement range | 0 - 100% as specified by customer |

| Accuracy | ± 2% of reading or ± 5% full scale |

| Repeatability | ± 1% of reading or ± 5% full scale |

| Stability - 24-hour period | ± 0.5% full scale zero drift (maximum) ± 1% full scale span drift (maximum) |

| Stability - 90-day period | ± 1% full scale zero drift (typical) ± 2% full scale span drift (typical) |

| Output noise (RMS) | Less than 0.5% full scale |

| Response time | Less than 10 seconds (electronic) |

| Warm-up time | Less than 1 hour |

| Temperature range | -40° F to 140° F (-40° C to 60° C) |

| Gas Sample Requirements | |

| Flow rate | 2 scfh (1 LPM) - recommended 4 scfh (2 LPM) - maximum |

| Moisture | 0 to 99% non-condensing |

| Output | |

| Analog | 0 to 100mV standard

0V - 1V, 0V - 5V (optional) 4-20mA (isolated) |

| Digital | RS232 bi-directional |

| Alarms | Optional |

| Gas Flow System | |

| Connections | Sample inlet - 1/4" compression fitting

Sample outlet - 3/8" or 1/4" compression fitting |

| Materials | 316 SS, sapphire, Teflon, Viton, polypropylene (typical) |

| Standard Gases | CO2, HC, CO, O2, NOx, Butane, Propane, Methane |

| Power | 90V - 260V AC maximum, 117 Vrms ± 10%, 50 Hz - 60 Hz |

| Enclosure (W x L x D) | 10.25" x 10.25" x 9" (26 cm x 26 cm x 22.86 cm) enclosure with display window and attached 3.5" x 2.5" junction box; NEMA 7 (C:, Grp D, E Div 1, 2) |

| Weight | 25 lbs. (11.35 kg) |

| Warranty | Infrared Industries, Inc. warrants each gas analyzer it manufactures to be free of defects in material and workmanship for a period of one (1) year from the date of delivery. Abuse, misuse or unauthorized changes excluded. Extended warranty available. |

Industries

News

Parts

Template: single-product.php